Weyburn – The Weyburn Unit’s discovery hole was spudded 65 years ago, and for 37 of those years, Key Well Servicing has been working in that field.

Key is currently owned by Kelsey Gerle and Gabe Runge, who purchased the company from Lyman Sargent and Toby Towne in November 2007. Gerle pointed out it has always been a locally-owned and operated company.

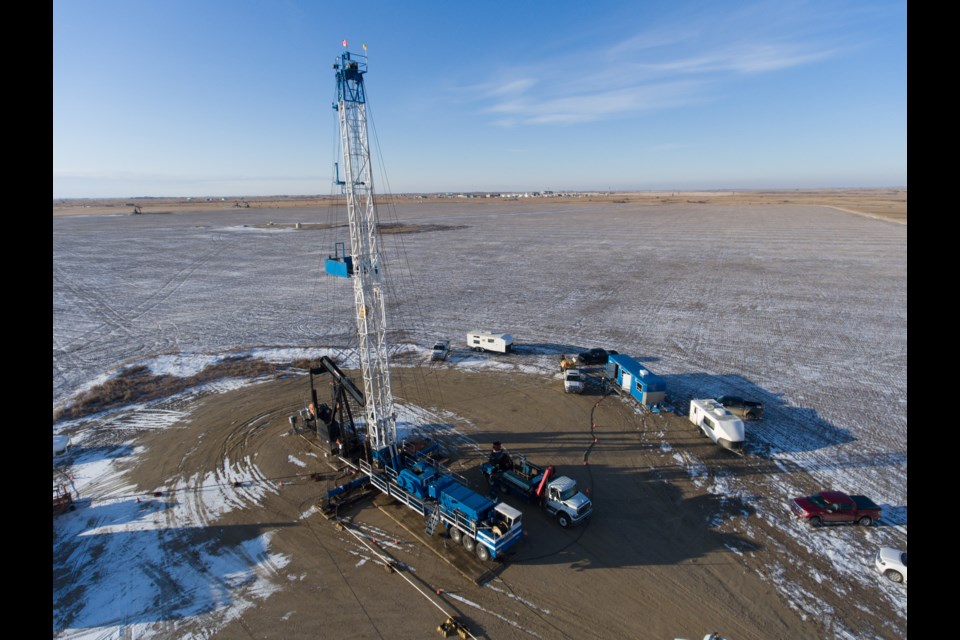

Key is a four-service rig outfit, primarily composed to two singles and two doubles. Recently, the doubles have been seeing more work, as they have been preferred by the oil companies. But that has changed over the history of the company, with singles in favour some years, and doubles in other years.

Their shop is on the Laurier Road, west of the Unit, and they have an office in Weyburn. The shop’s location places it relatively close to the Unit, but more importantly, as it is in the same rural municipality as the Unit, road permits are less of an issue.

Runge started working with Key in December 2000. Gerle had been working on drilling rigs for many years, but his rig went to work in northern Alberta, so he found work with Key on the service rigs. Gerle is originally from Ceylon and Runge is originally from Trossachs. Now they and their families call Weyburn home.

They bought Key in 2007, just in time to ride the roller coaster of oil prices, from a record high to a harsh low.

“It was a record high to a record low within the first year,” said Gerle.

They had the two singles initially. They bought the two double-triples (double joint, triple rod capable) in 2013, and also added a flushby and a pressure truck. “We had two flushbys for a while, then it slowed down, so we ended up selling one,” Gerle said.

“It went to Mexico, and we should have went with it,” he said with a laugh.

To work or for a holiday?

“Both!” they exclaimed together.

“We should have sold the rigs and bought a resort,” Runge said, smiling.

There’s not much market for singles these days in the southeast. “Smaller companies that have shallower wells and quick pump changes, but they’re just waiting,” Gerle said.

If they were to sell the two singles, they would get another double, but they don’t expect that to happen any time soon. “You would need a huge turn in the economy, too,” said Runge. “There’s so many rigs sitting.”

They’re fully staffed right now. “If we were to have Rig 1 go out tomorrow, we’d be short five guys. We have one extra guy right now. But if Rig 1 went out, we’d need a full crew.”

They also have a part-timer come in as needed.

“There’s no schedule. It could be 21 days on, or four days a week. There’s no set schedule. If a big well goes down, you’re working the weekend. If not, you have the weekend off. Maybe a long weekend. Just whatever comes along, I guess,” Gerle said. “We try to do a 10 and four, but we’ve tried so many schedules that didn’t work.”

“It depends on the price of oil,” Runge added.

“As soon as we’d have the four days off, a well would go down, and it just didn’t work,” Gerle said.

“We tell them right away, there’s no set schedule.”

If a worker has something important coming up, they need to book the time off so someone else can fill in, because they can’t count on having the weekend off.

They pay par or a little better than the Canadian Association of Oilwell Drilling Contractors’ recommended wage scale.

Key has 17 employees, including the two owners.

“We have a lot of older guys, a lot of long-term,” Gerle said. One is in his 60s.

“We have had some turnover, for sure,” Gerle said. “But we still employ great, long-term employees. We’re a family oriented business. On one rig, we have an uncle and a nephew. On another rig, we have a father and son.”

“Nothing like it was in 2012-13,” Runge added. “It was really new faces then. It’s stable now.”

“A few guys that had worked went back to school. We had a couple guys from Ontario take off and are not even around anymore,” Gerle said.

The flushby generally works Monday to Friday. “It’s steady,” Gerle said.

While flushby units are common in northwest Saskatchewan, they are not common in the southeast. “Ours isn’t really for pump changes. We do more unseat, and pump chemical, to deal with the wax in this field,” Runge said.

Gerle added the flushby is also used for high rod breaks.

“We only work in this field right now,” Runge said. “We have, in the past, ventured out for other companies.”

The work has been steady.

Asked if two people walked in tomorrow, looking for work, would they take them, Gerle responded, “If we had the work, we definitely would. It’s such a hard thing to say. If we had a phone call and an oil company said we wanted Rig 1, and we’re hoping it’s going to go out, we’d be gathering every resumé we can.”

“You get us those two guys, and we’ll let you know!” Runge said with a laugh.

Gerle likes the idea of having a pool of three men who are oriented to three service rig companies, for example, who could be called up to work around between those three companies. “If, as a service rig company, we could keep three good guys busy, if they wanted to move around… We have one guy who would rather move around for us and keep busy, than stick with one particular rig. He likes change. If we had three of them that could move to different companies, and have all their tickets and orientated, it would be easier.

“We all get along,” he said of his local competitors.

Offering an idea, Gerle said, “If you had a five guys, a full crew, that work well together, then you could have it where if that rig goes to work, and shuts down, they go to the next one. And if they are sitting, and nobody has work, then each company has to throw in a little bit.

“Each takes one,” Runge said.